Large-scale multi-storey plastic greenhouses are a type of greenhouses that have appeared in the past ten years and have received rapid economic development of enterprises. Compared with glass greenhouses, it has the advantages of light weight, less use of skeleton materials, small shading rate of structural parts, low cost, and long service life. Its environmental management regulation learning ability analysis can basically reach the same living standard as glass greenhouses. The use of film greenhouses is far higher than that of glass greenhouses all over the world, and has become the mainstream of the development of China's modern agricultural greenhouse industry.

Thin-film intelligent multi-span greenhouse is a modern planting greenhouse based on traditional linkage greenhouses, integrating modern IoT sensor end points, communication technology, IoT control end points, environmental control equipment, and IoT monitoring platforms. General configuration of external shading system, internal shading system, internal thermal insulation system, wet curtain fan forced ventilation and cooling system, top ventilation system, heating system, power distribution/control system and other highly automated facilities, in the process of intelligent greenhouse work, managers According to the production process of different crops, the process parameters are set through the cloud platform, and the intelligent greenhouse can realize unmanned automatic operation, automatically control the greenhouse environment, and ensure the growth of crops.

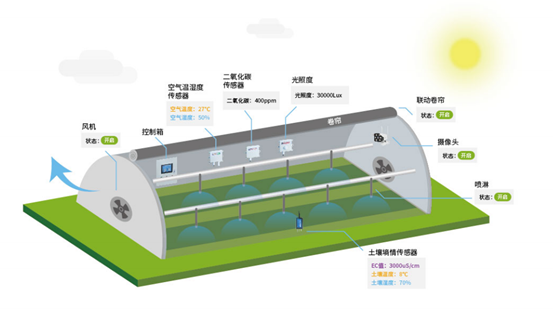

In the process of automatically controlling the greenhouse environment, relying on modern Internet of Things sensors to realize remote real-time monitoring of greenhouse environmental data, the control equipment in each unit system is installed by installing electric film rollers, axial fans, ring network fans, sunshade nets, heating Equipment realizes environmental regulation.

Greenhouse environment sensor

Sensor Type | Picture | Parameter | Description |

CO2 |

| Measuring range | 0-2000ppm |

Measuring range | ±(50ppm+3%Reading) | ||

Illuminance |

| Measuring range | 0-18.8萬lux |

Humidity accuracy | 0.45lux | ||

Air temperature and humidity |

| Measuring range | -40-120℃ |

Humidity accuracy | ±0.3℃ | ||

Measuring range | 0-100% | ||

Humidity accuracy | ±3.0% | ||

Soil temperature and humidity |

| Measuring range | -30-70℃ |

Humidity accuracy | ±0.2℃ | ||

Measuring range | 0-100% | ||

Humidity accuracy | ±2.0% |

Environmental monitoring equipment

Electric film roller

The waste heat and moisture in the greenhouse are removed by raising and lowering the top/side electric film rollers, so that the ambient temperature in the greenhouse is kept within the range suitable for plant growth; adjust the air composition in the greenhouse, discharge harmful gases, and improve the air in the greenhouse. The freshness of the air and natural ventilation.

Sunshade net

The motor drives the transmission shaft to run through the transmission mechanism. The transmission shaft drives the drive rod to move in parallel on the curtain wire through the connector. The drive rod pulls one end of the curtain to slowly expand. After all deployments, the stroke limiter switch is touched, the motor stops, and the stroke runs. The control box is equipped with manual control. If you need to stop halfway, you can press the stop button to stop the operation.

Inner shade

In summer, the use of thermal insulation shading curtains can reflect some of the excess sunlight, and allow sunlight to diffuse into the greenhouse, which not only ensures the normal growth of crops, but also reduces indoor energy accumulation, thereby reducing the temperature in the greenhouse, protecting crops from strong light burns, and making The indoor temperature drops by 3-5 ° C. In winter, the thermal insulation shading curtain has the effect of preventing the escape of indoor infrared rays and reducing the loss of radiant heat on the ground, thereby increasing the indoor temperature, reducing energy consumption, and greatly reducing the operating cost of the greenhouse in winter. By selecting different curtains or adjusting the opening and closing of the curtains, different shading rates can be achieved to meet the needs of different crops for sunlight.

Wet Curtain/Fan

The wet curtain/fan cooling system uses the evaporative cooling principle of water to achieve the purpose of cooling. The system uses wet curtains, water pumps and large-flow fans. The core of the cooling system is to ensure that the water evenly wetting the entire wet curtain wall. When the air passes through the wet curtain medium, the water vapor exchange with the surface of the wet curtain medium reduces the temperature of the air, which is the most economical and effective cooling method.

Fog spray

The mobile mist spray system is used for irrigation, humidification and cooling of seedling greenhouses. Each building is set multiple times according to the span of the greenhouse, and is individually controlled by solenoid valves.

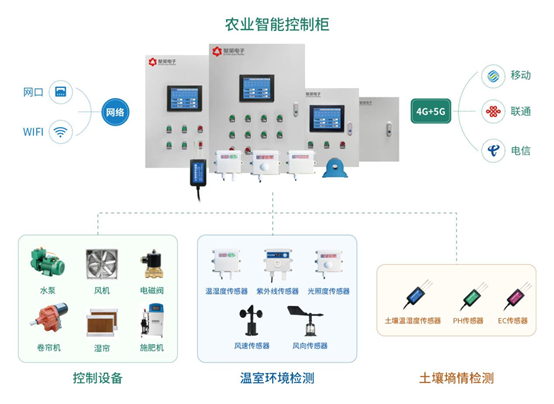

Greenhouse intelligent control cabinet

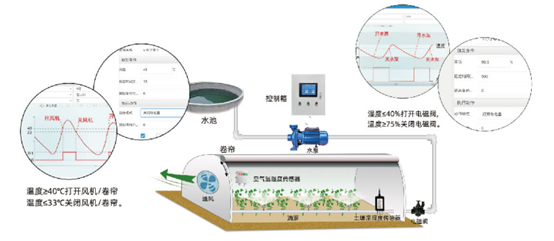

The intelligent monitoring cabinet of Juying greenhouse collects sensor data. The collection methods include RS485 wired method and wireless LORA communication method. It has built-in intelligent algorithm and PLC intelligent automatic control function, which can automatically determine the upper and lower thresholds of sensor data and automatically output control signals to the environment. Control equipment to realize equipment linkage.

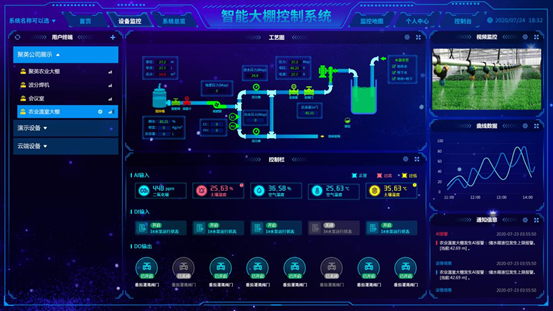

Internet of Things Monitoring Platform

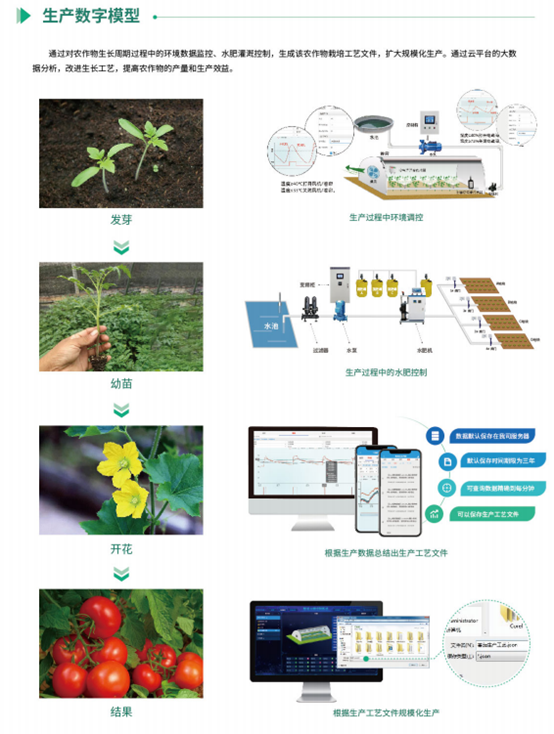

Production process

Due to the different growth environment requirements of different crops, the environmental parameter requirements of different growth stages of crops are also different. In greenhouse farming, the regulation of environmental parameters during the growth process of these crops is called the production process of crops. Traditional greenhouses are managed manually, and crop environmental regulation needs to be managed by manual viewing of digital instruments, which is non-replicable and popularized.

The intelligent monitoring system of Juying greenhouse realizes the controllability and replication of the digital model of crop production through the built-in intelligent algorithm and the big data EdgeComputing function of the Juying Agricultural Internet of Things platform, realizes the factory greenhouse planting mode, and improves profitability and returns.

銷售王經(jīng)理

銷售王經(jīng)理

微信公眾號(hào)

微信公眾號(hào)